An oil-free compressor is only one of several types of compressors available. It works the same way as a standard air compressor, and may even look very similar on the outside; internally, however, it contains special seals designed to keep the crucial lubricating oil away from the compressed air. The moving parts inside the compressor require lubrication to reduce the friction.

Lubrication is essential in adequate amounts, regardless of the type of compressor, in order to prevent failure of the parts. The term oil-free refers to the air that the compressor produces, not the machine itself.

Oil Free Air Compressors are air compressors specifically developed for applications where air quality is essential for end-product and production processes. Industries such as pharmaceuticals, food and beverage, electronics and textiles cannot risk any chance of oil contamination in their processes. Therefore, it is essential that the compressed air is 100% oil-free. The standard is ISO 8573-1 (2010) certification, in which Class Zero represents the highest air purity. It is the only way to ensure oil-free air for critical processes and with it peace of mind. Outstanding reliability, low maintenance and operating costs make oil-free compressors a sound investment.

In recent decades, there has been more and more research on the oil-free screw air compressor. According to the type of lubrication, the Screw type air compressor has two kinds: the water-lubricated single-screw type and the dry twin-screw type.

For the Dry oil-free screw air compressor, most are twin-screw air compressors. Water-lubricated oil-free screw air compressor is also called a water-injected screw air compressor, most are single screw air compressors. The following analyze their differences:

Water-injected Oil-free Single Screw Air Compressor vs Dry Oil-free Double Screw Air Compressor

Working Principle

| Comparison | Water-lubricated Oil-free Single Screw | Dry Oil-free Double Screw |

| Air Quality | 100% Oil-Free | Oil in the gear |

| Air Purity | Clear air after purified by water | Contain dust and oil stain |

| Lubrication Media | Pure Water | Dry |

| Air Temp | Less than 55℃ | About 180~200℃ |

| Compression | Single-Stage | Two-stage |

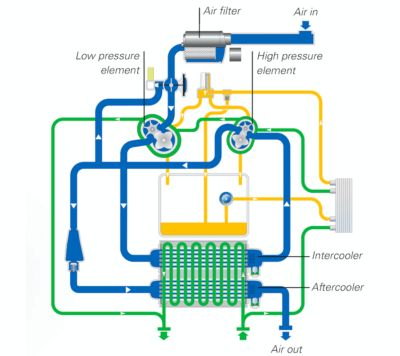

| Cooling method | Don’t need a cooling system | Need interstage and after Cooling system |

| Structure | Simple and Balanced Structure | Radial load is not balance |

| Vibration and Noise | Low vibration and noise | High-frequency noise due to the two screws |

| Durability | Ideal Rotation speed 3000r/min, theoretically zero loads.Long lifetime of the screw (30000h) and star wheel (50000h) | Rotation speed 18000r/min, high loads on screws.The short lifetime of the screw (8000~18000h) |

| Maintenance | Only air and water filter elements | More spare parts |

Different principles

1.The dry oil-free screw air compressor means that the coating on the surface of the rotor teeth will play the role of lubrication and sealing. There is no lubrication medium in the compression chamber. But there is lubricating oil in the gearbox;

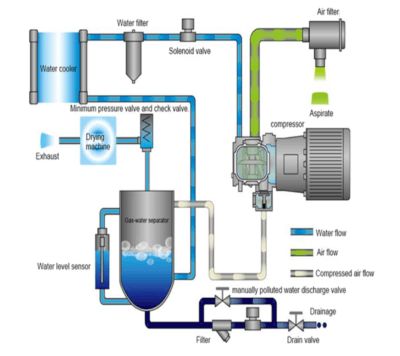

2.But for the Water-lubricated oil-free type means that the water and air are mixed and compressed. Water plays the role of lubricating, sealing, cooling, and denoising.

Different Prices

1.Water-lubricated oil-free type is mostly single-screw air compressors. The price is generally lower than the dry oil-free type. The maintenance cost is also lower. Only air filter elements and water filter elements.

2.But for the dry oil-free air compressor, except for the spare parts, the coating also needs to be replaced regularly.

Different Losses

1.Water-injected oil-free single screw type: ideal isothermal compression, no heat loss.

2.Dry oil-free double screw type: energy lost due to hot air discharge

Post time: Sep-20-2023