Oil-Injected Screw Type 7.5kw 15kw 22kw 37kw 75kw Air Compressor 8bar 10bar 13bar

* Five-in-one air compressor for laser cutting

* Variable frequency, explosion-proof, low noise, others

* High-pressure cooling system, high heat dissipation efficiency, can work continuously for 24 hours no matter in high temperature and high humidity environment

* OEM support

* One-stop service

Bobair VSD rotary screw air compressor are suitable for customers who need different amount of air supply and extremely accurate pressure. It can facilitate customers to optimize production process and improve productivity.

1. Easy to install and Maintain.

2. High performance. Our models provide more air and consumes less energy, providing your sustainable, high quality air to run your operations.

3. Reliable.

4. ≥30% energy saving.

Heavy & light industry, mining, hydropower, seaport, engineering construction, oil and gas fields, railways, transportation, shipbuilding, energy, military industry, spaceflight, and other industries.

(1) Intelligent Control System

Direct display of discharge temperature and pressure, operating frequency, current, power, operating state. Real-time monitoring of discharge temperature and pressure, current, frequency fluctuations.

(2) The Latest Generation High-Efficiency Permanent Motor

Insulation grade F, protective grade IP54. IP55, suitable for the bad working conditions. No gearbox design, motor, and main rotor through the coupling directly connected, high transmission efficiency. Wide range of speed regulation, high precision, a wide range of airflow regulation. The efficiency of the permanent magnet motor is higher 3%-5% than the regular motor, efficiency is constant, when the speed drops, still remain the high efficiency.

(3) The Latest Generation Super Stable Inverter

Constant pressure air supply, air supply pressure is accurately controlled within 0.01Mpa. Constant temperature air supply, general constant temperature set at 85℃, make the best oil lubrication effect and avoid high temperature to stop. No empty load, reduce energy consumption by 45%, eliminate excess pressure. For each 0.1 mpa increase of air compressor pressure, energy consumption increases by 7%. Vector air supply, accurate calculation, to ensure that the air compressor production and customer system air demand at all times to maintain the same.

(4) Wide Working Frequency Range To Save Energy

Frequency conversion ranges from 5% to 100%. When the user s gas fluctuation is large, the more obvious the energy-saving effect and the lower the low-frequency running noise, applicable to any place.

(5) Small Start-up Impact

Use frequency conversion permanent magnet motor, start smooth and soft. When the motor starts, the current does not exceed the rated current, which does not affect the power grid and the mechanical wear of the main engine greatly reduces the power failure and prolongs the service life of the main screw machine.

(6) Low Noise

The inverter is a soft start device, the start-up impact is very small, the noise will be very low when start-up. At the same time, the PM VSD compressor running frequency is less than the fixed speed compressor during stable operation, mechanical noise decreases very much.

The brand “BOBAIR, specializes in the R&D, manufacturing, sales and service of compressors, oil-free compressors and air end, special gas compressors, various air compressors and post-processing equipment, providing customers with High-quality, environmentally friendly and efficient air system solutions and fast and stable technical services.

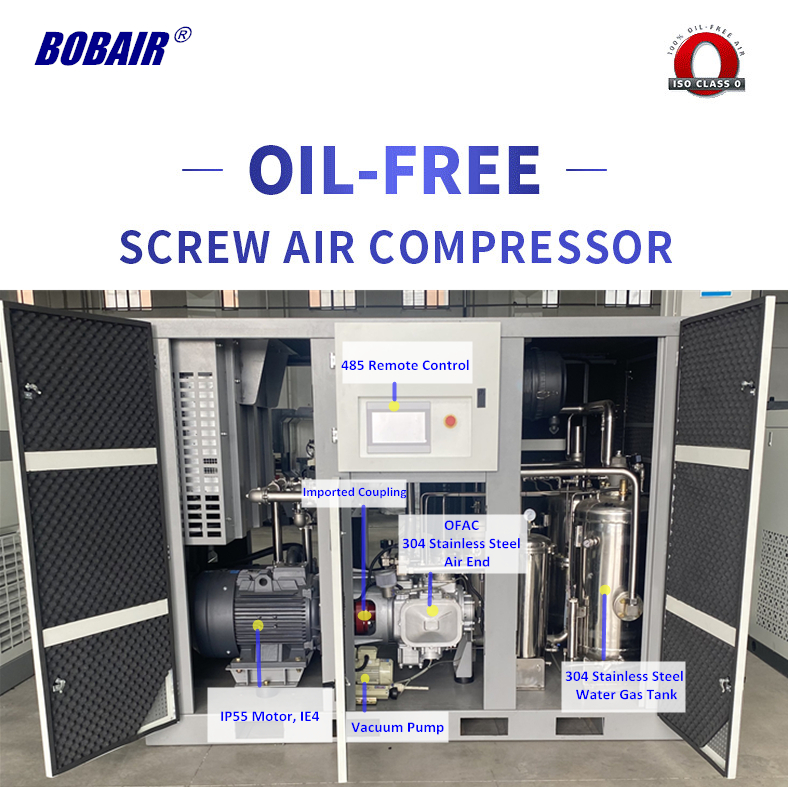

Why Choose BOBAIR Oil-free Screw Air Compressor

1. Mitsui technology, can replace Mitsui air end 1:1.

2. Highest ultra precision air end manufacturer in China, failure rate nearly 0.

3. Comes with 3-stage purifier, tap water(daily used water) is workable.

4. Easiest maintenance, 0 Emission.

5. simple structure, easy to use.

6. with 485 remote switch.

Jiangxi Bobai has launched a completely new range of high efficiency, oil-free two-stage rotary screw compressors to further enhance its successful. These high output oil-free machines now cover a wide flow range from 6.0 to 40.0m3/min, the pressure range from 20bar to 40bar.

High-pressure compressed air is used for blowing bottles.

The pressure depends on the container’s design, wall thickness, blow speed, and so on. The bottles with thick walls, sharp edges, and special shapes need higher pressure. Generally, the stretch blow molding requires about 10~25bar for pre-blowing and about 40bar for the bottle-blowing process. The trend for PET bottle-blowing machines is to reduce the blow pressure as much as possible for energy saving.

The bottles should be cleaned with compressed air before filling the water, beverage, cooking oil and so on.

If the air is contaminated, it will influence the flavor and odor, causing health problems.

For screw type, the air is compressed to 7~8bar at the first screw compression stage, there is no need to cool and the air goes into the second stage screw air end, finally achieving 30~40bar air discharge directly without cooling. Rotation speed 3000r/min, zero loads. About 50℃, no heat waste, Ideal isothermal compression.